Yeah, I'm having trouble understanding it, too. Looks to me like its sitting 90* out of phase with the original unit in both shots.

Jim

Yeah, I'm having trouble understanding it, too. Looks to me like its sitting 90* out of phase with the original unit in both shots.

Nope, they are sitting the same, in the left picture on the Vintage Air unit the three-round things you see toward the left side are duct hookups coming out of the top on the unit, in the right picture the blower is where the fresh air door is on the original, maybe the confusion is because the two halves are different, the original there is a front and back and on the VA unit it has a top and bottom, also the stock heater is sitting crooked because it is resting on the blower motor.Jims65cyclone wrote: ↑Fri May 29, 2020 8:39 pmYeah, I'm having trouble understanding it, too. Looks to me like its sitting 90* out of phase with the original unit in both shots.

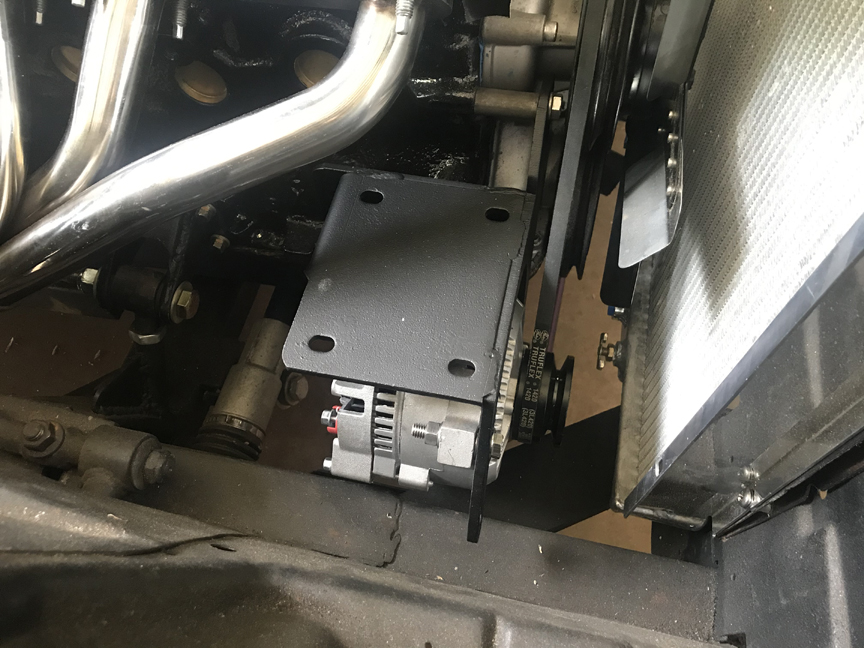

A lot of the list is going to clear rapidly because I am just bolting stuff together no fabrication required#4 - Assemble the rocker arm shaft (it was taken apart for a thorough cleaning) At this point I need to do any alterations in the engine bay like cutting the exhaust pipes off shorter, I need to modify the transmission opening in the floor as well to give more shifter clearance on one side, I am also going to modify the motor mounts again by adding more reinforcement, I feel the metal is too thin on the sides.

C&G had them for $10 a pair so I ordered some, they came today and I got them installed, they don't exactly look like the ones that came off but I think they are correct and mine are just so bad and deformed that is what mine are supposed to look like.I really need the two trunk bumpers but have been able to find them yet, so for now I cleaned them and painted them with Plasti-Dip, don't even know if the paint will stay on them but they look slightly better but they are still dry and cracked.

It's coming I just need to stop procrastinating on it, there is so much to do it seems like that I never quite get to it, I think what slows me down on it is there is a lot to do prior too, like getting the flasks built and coming up with several 100? pounds of greensand, etc. obviously the day will come soon that I have to work on it.Jims65cyclone wrote: ↑Thu Jun 18, 2020 8:00 pmWhat's the status on getting your intake manifold cast? Or are you just going to stick with the wooden one?

Jim